Driving Growth in Agriculture & Manufacturing with Innovative Tech Solutions

Leveraging cutting-edge technology to transform traditional sectors into efficient, sustainable, and digitally-enabled industries.

Leveraging cutting-edge technology to transform traditional sectors into efficient, sustainable, and digitally-enabled industries.

Opticbee stands at the intersection of traditional industries and digital innovation, creating powerful synergies between agriculture and manufacturing sectors. Our integrated approach leverages IoT, AI, and automation to drive unprecedented efficiency, sustainability, and profitability across both domains. By connecting farm-to-factory operations through seamless data exchange, we enable real-time decision making that optimizes resource allocation, reduces waste, and maximizes output quality.

In agriculture, our solutions help farmers increase yields while minimizing environmental impact through precision farming techniques. In manufacturing, we enable smart factories that respond dynamically to supply chain fluctuations and market demands. The convergence of these sectors through Opticbee's technology platform creates a resilient ecosystem where agricultural outputs become optimized manufacturing inputs, reducing costs and enhancing sustainability across the entire value chain.

Our platform creates seamless connectivity between agricultural production and manufacturing processes, ensuring optimal resource utilization from field to finished product.

Opticbee's Agri-Tech solutions revolutionize traditional farming through smart technology integration. Our IoT-based crop monitoring systems provide real-time data on soil conditions, moisture levels, and plant health, enabling precision agriculture that reduces water usage by up to 30% while increasing yields. AI-driven predictive analytics forecast optimal planting and harvesting times, potential disease outbreaks, and yield projections with remarkable accuracy.

Our farm-to-market supply chain optimization platform connects farmers directly with distributors and processors, reducing intermediaries and increasing profit margins for agricultural producers. Drones equipped with multispectral imaging identify problem areas in fields before they become visible to the human eye, allowing for targeted intervention that minimizes chemical usage. These technologies collectively contribute to sustainable farming practices that protect environmental resources while maximizing productivity.

Smart irrigation systems that reduce water usage by monitoring soil moisture and weather conditions in real-time.

GPS-guided equipment and sensor networks that enable exact input application and cultivation techniques.

Comprehensive sensor networks that provide continuous data on crop health, soil conditions, and microclimates.

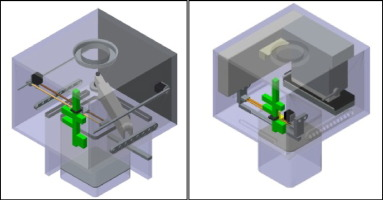

Opticbee's manufacturing solutions embrace Industry 4.0 principles to create intelligent, connected production environments. Our automation systems streamline operations from raw material handling to finished product packaging, significantly reducing labor costs and human error. Integrated robotics work alongside human operators to enhance precision in repetitive tasks while allowing skilled workers to focus on quality control and process optimization.

Predictive maintenance algorithms analyze equipment sensor data to forecast potential failures before they occur, minimizing downtime and extending machinery lifespan. Our ERP solutions provide real-time visibility across production floors, inventory management, and supply chain logistics, enabling just-in-time manufacturing that reduces storage costs and improves cash flow. These technologies collectively transform traditional factories into agile, responsive manufacturing hubs capable of adapting quickly to changing market demands and custom orders.

94.7%

12,847

99.2%

Optimized

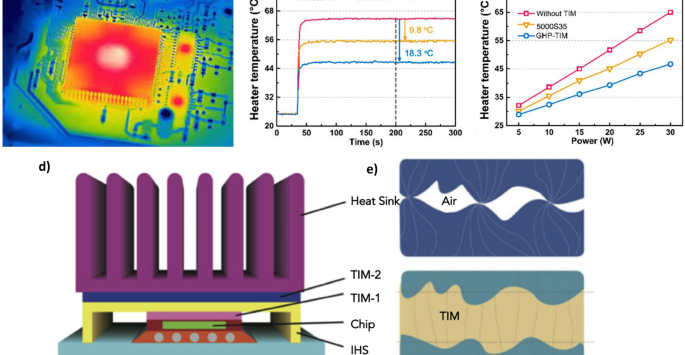

Opticbee's industrial solutions cater to heavy industries requiring robust, reliable technology infrastructure. Our plant monitoring systems utilize thousands of IoT sensors to track equipment performance, environmental conditions, and production metrics in real-time. This comprehensive data ecosystem enables plant managers to optimize energy consumption, reduce waste, and maintain consistent product quality across continuous operation cycles.

Safety and compliance are paramount in industrial settings, and our solutions include automated compliance tracking, hazard detection systems, and emergency response coordination. Real-time analytics transform raw operational data into actionable insights, predicting maintenance needs and identifying efficiency improvements. For energy-intensive industries, our optimization algorithms can reduce power consumption by up to 25% while maintaining or even increasing output levels. These technologies create industrial environments that are not only more productive but also safer for workers and more sustainable for surrounding communities.

Advanced systems that detect potential hazards, ensure compliance with safety protocols, and coordinate emergency responses in industrial environments.

Intelligent systems that analyze energy consumption patterns and automatically adjust equipment settings to minimize waste while maintaining production levels.

Opticbee's construction management solutions bring digital transformation to the building industry through integrated software platforms that coordinate all aspects of construction projects. Our Building Information Modeling (BIM) integration creates detailed digital twins of physical structures, allowing for precise planning, clash detection, and resource allocation before ground is ever broken. This proactive approach identifies potential issues in the design phase, reducing costly changes during construction.

Project lifecycle tracking provides real-time visibility into progress, budget adherence, and resource utilization across multiple construction sites. Automated documentation ensures compliance with building codes and regulations while reducing administrative overhead. Safety monitoring systems use IoT sensors and computer vision to identify potential hazards and ensure protocol compliance. These technologies collectively enable construction firms to deliver projects on time, within budget, and with enhanced structural integrity and safety standards.

With sustainability at the core, Opticbee leverages digital simulations to optimize energy use, minimize material waste, and reduce the carbon footprint of construction projects. These capabilities not only support compliance with environmental regulations but also position construction firms as leaders in sustainable development. By combining innovation with practical efficiency, Opticbee empowers the building industry to deliver smarter, safer, and more resilient infrastructure.

Digital blueprint creation, resource planning, and regulatory compliance checks using BIM technology.

Automated surveying, ground analysis, and foundation planning with precision mapping tools.

Real-time progress tracking, resource management, and quality control throughout building execution.

Final inspection automation, documentation generation, and digital twin creation for facility management.

Advanced modeling for precise planning and execution

Real-time monitoring of timelines and budgets

Automated compliance and standards verification

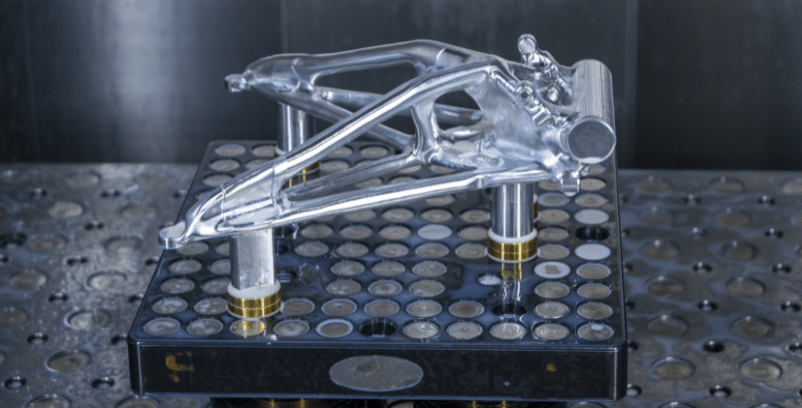

Opticbee's metallurgy solutions leverage advanced material science and digital monitoring to enhance metal production and processing. Our quality testing systems utilize non-destructive testing methods, spectroscopic analysis, and computerized tomography to detect imperfections at microscopic levels, ensuring material integrity before components enter critical applications. Production monitoring systems track every stage of metallurgical processes, from smelting and alloying to forming and finishing.

For automotive and aerospace industries, our solutions enable the production of lighter, stronger alloys that improve fuel efficiency and performance while maintaining safety standards. In infrastructure applications, our monitoring systems ensure structural metals meet exacting specifications for longevity and resilience. Predictive analytics optimize furnace operations, reducing energy consumption while maintaining precise temperature profiles essential for alloy consistency. These technologies transform traditional metallurgy into a data-driven science, producing advanced materials with properties tailored to specific industrial applications.

Advanced monitoring systems for producing high-strength, corrosion-resistant steel variants for construction and manufacturing applications.

Precision alloy production for aerospace and automotive industries requiring high strength-to-weight ratios and thermal resistance.

Hybrid material systems combining metallic and non-metallic components for specialized applications in extreme environments.